Artículo

Optimal shutdown policy for maintenance of cracking furnaces in ethylene plants

Fecha de publicación:

04/2006

Editorial:

American Chemical Society

Revista:

Industrial & Engineering Chemical Research

ISSN:

0888-5885

Idioma:

Inglés

Tipo de recurso:

Artículo publicado

Clasificación temática:

Resumen

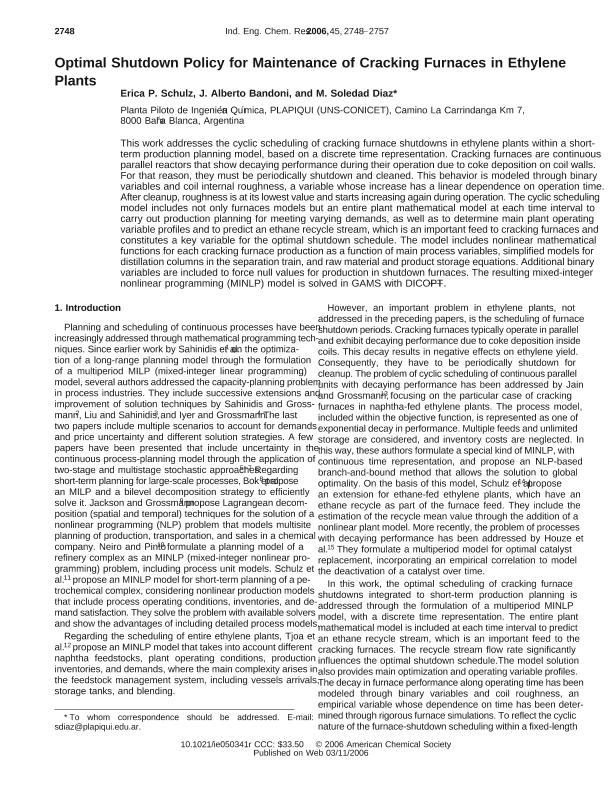

This work addresses the cyclic scheduling of cracking furnace shutdowns in ethylene plants within a short-term production planning model, based on a discrete time representation. Cracking furnaces are continuous parallel reactors that show decaying performance during their operation due to coke deposition on coil walls. For that reason, they must be periodically shutdown and cleaned. This behavior is modeled through binary variables and coil internal roughness, a variable whose increase has a linear dependence on operation time. After cleanup, roughness is at its lowest value and starts increasing again during operation. The cyclic scheduling model includes not only furnaces models but an entire plant mathematical model at each time interval to carry out production planning for meeting varying demands, as well as to determine main plant operating variable profiles and to predict an ethane recycle stream, which is an important feed to cracking furnaces and constitutes a key variable for the optimal shutdown schedule. The model includes nonlinear mathematical functions for each cracking furnace production as a function of main process variables, simplified models for distillation columns in the separation train, and raw material and product storage equations. Additional binary variables are included to force null values for production in shutdown furnaces. The resulting mixed-integer nonlinear programming (MINLP) model is solved in GAMS with DICOPT++.

Archivos asociados

Licencia

Identificadores

Colecciones

Articulos(PLAPIQUI)

Articulos de PLANTA PILOTO DE INGENIERIA QUIMICA (I)

Articulos de PLANTA PILOTO DE INGENIERIA QUIMICA (I)

Citación

Schulz, Erica Patricia; Bandoni, Jose Alberto; Díaz, María Soledad; Optimal shutdown policy for maintenance of cracking furnaces in ethylene plants; American Chemical Society; Industrial & Engineering Chemical Research; 45; 8; 4-2006; 2748-2757

Compartir

Altmétricas