Mostrar el registro sencillo del ítem

dc.contributor.author

Cañete, Benjamin

dc.contributor.author

Gigola, Carlos Eugenio

dc.contributor.author

Brignole, Nélida Beatriz

dc.date.available

2017-11-21T18:25:04Z

dc.date.issued

2017-05-15

dc.identifier.citation

Cañete, Benjamin; Gigola, Carlos Eugenio; Brignole, Nélida Beatriz; Enhancing the Potential of Methane Combined Reforming for Methanol Production via Partial CO 2 Hydrogenation; American Chemical Society; Industrial & Engineering Chemical Research; 56; 22; 15-5-2017; 6480-6492

dc.identifier.issn

0888-5885

dc.identifier.uri

http://hdl.handle.net/11336/28653

dc.description.abstract

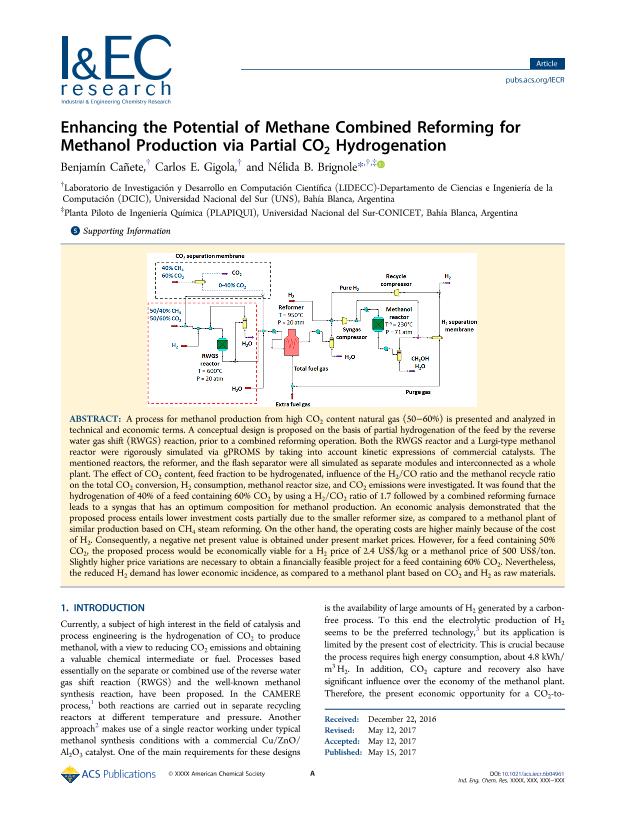

(Figure Presented) A process for methanol production from high CO2 content natural gas (50-60%) is presented and analyzed in technical and economic terms. A conceptual design is proposed on the basis of partial hydrogenation of the feed by the reverse water gas shift (RWGS) reaction, prior to a combined reforming operation. Both the RWGS reactor and a Lurgi-type methanol reactor were rigorously simulated via gPROMS by taking into account kinetic expressions of commercial catalysts. The mentioned reactors, the reformer, and the flash separator were all simulated as separate modules and interconnected as a whole plant. The effect of CO2 content, feed fraction to be hydrogenated, influence of the H2/CO ratio and the methanol recycle ratio on the total CO2 conversion, H2 consumption, methanol reactor size, and CO2 emissions were investigated. It was found that the hydrogenation of 40% of a feed containing 60% CO2 by using a H2/CO2 ratio of 1.7 followed by a combined reforming furnace leads to a syngas that has an optimum composition for methanol production. An economic analysis demonstrated that the proposed process entails lower investment costs partially due to the smaller reformer size, as compared to a methanol plant of similar production based on CH4 steam reforming. On the other hand, the operating costs are higher mainly because of the cost of H2. Consequently, a negative net present value is obtained under present market prices. However, for a feed containing 50% CO2, the proposed process would be economically viable for a H2 price of 2.4 US$/kg or a methanol price of 500 US$/ton. Slightly higher price variations are necessary to obtain a financially feasible project for a feed containing 60% CO2. Nevertheless, the reduced H2 demand has lower economic incidence, as compared to a methanol plant based on CO2 and H2 as raw materials.

dc.format

application/pdf

dc.language.iso

eng

dc.publisher

American Chemical Society

dc.rights

info:eu-repo/semantics/openAccess

dc.rights.uri

https://creativecommons.org/licenses/by-nc-sa/2.5/ar/

dc.subject

Co2 Utilization

dc.subject

Rwgs

dc.subject

Combined Reforming

dc.subject

Methanol

dc.subject

Npv Analysis

dc.subject.classification

Otras Ingeniería Química

dc.subject.classification

Ingeniería Química

dc.subject.classification

INGENIERÍAS Y TECNOLOGÍAS

dc.title

Enhancing the Potential of Methane Combined Reforming for Methanol Production via Partial CO 2 Hydrogenation

dc.type

info:eu-repo/semantics/article

dc.type

info:ar-repo/semantics/artículo

dc.type

info:eu-repo/semantics/publishedVersion

dc.date.updated

2017-11-03T19:34:09Z

dc.journal.volume

56

dc.journal.number

22

dc.journal.pagination

6480-6492

dc.journal.pais

Estados Unidos

dc.description.fil

Fil: Cañete, Benjamin. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina. Universidad Nacional del Sur. Departamento de Ciencias e Ingeniería de la Computación. Laboratorio de Investigación y Desarrollo en Computación Científica; Argentina

dc.description.fil

Fil: Gigola, Carlos Eugenio. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina. Universidad Nacional del Sur. Departamento de Ciencias e Ingeniería de la Computación. Laboratorio de Investigación y Desarrollo en Computación Científica; Argentina

dc.description.fil

Fil: Brignole, Nélida Beatriz. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina. Universidad Nacional del Sur. Departamento de Ciencias e Ingeniería de la Computación. Laboratorio de Investigación y Desarrollo en Computación Científica; Argentina

dc.journal.title

Industrial & Engineering Chemical Research

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/url/http://pubs.acs.org/doi/abs/10.1021/acs.iecr.6b04961

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/doi/http://dx.doi.org/10.1021/acs.iecr.6b04961

Archivos asociados