Mostrar el registro sencillo del ítem

dc.contributor.author

Rodriguez Aguilar, Leandro Pedro Faustino

dc.contributor.author

Cedeño Viteri, Marco Vinicio

dc.contributor.author

Sanchez, Mabel Cristina

dc.date.available

2017-10-23T18:49:48Z

dc.date.issued

2016-07-25

dc.identifier.citation

Rodriguez Aguilar, Leandro Pedro Faustino; Cedeño Viteri, Marco Vinicio; Sanchez, Mabel Cristina; Sensor location for enhancing fault diagnosis; American Chemical Society; Industrial & Engineering Chemical Research; 55; 32; 25-7-2016; 8830-8836

dc.identifier.issn

0888-5885

dc.identifier.uri

http://hdl.handle.net/11336/26925

dc.description.abstract

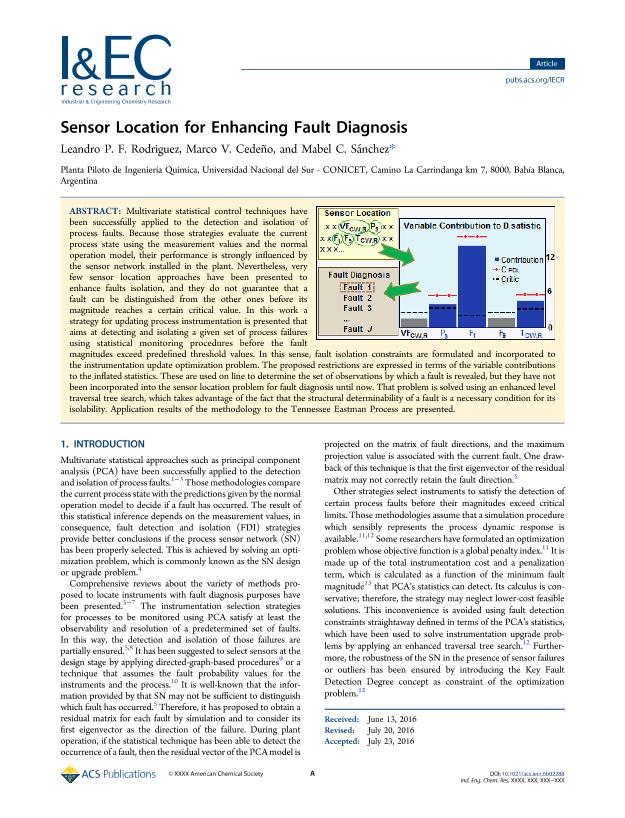

Multivariate statistical control techniques have been successfully applied to the detection and isolation of process faults. Because those strategies evaluate the current process state using the measurement values and the normal operation model, their performance is strongly influenced by the sensor network installed in the plant. Nevertheless very few sensor location approaches have been presented to enhance faults isolation, and they do not guarantee that a fault can be distinguished from the other ones before its magnitude reaches a certain critical value. In this work a strategy for updating process instrumentation is presented that aims at detecting and isolating a given set of process failures using statistical monitoring procedures before the fault magnitudes exceed predefined threshold values. In this sense fault isolation constraints are formulated and incorporated to the instrumentation update optimization problem. The proposed restrictions are expressed in terms of the variable contributions to the inflated statistics. These are used on line to determine the set of observations by which a fault is revealed, but they have not been incorporated into the sensor location problem for fault diagnosis until now. That problem is solved using an enhanced level traversal tree search, which takes advantage of the fact that the structural determinability of a fault is a necessary condition for its isolability. Application results of the methodology to the Tennessee Eastman Process are presented.

dc.format

application/pdf

dc.language.iso

eng

dc.publisher

American Chemical Society

dc.rights

info:eu-repo/semantics/openAccess

dc.rights.uri

https://creativecommons.org/licenses/by-nc-sa/2.5/ar/

dc.subject

Sensor Network Design

dc.subject

Principal Component Analysis

dc.subject.classification

Otras Ingeniería Química

dc.subject.classification

Ingeniería Química

dc.subject.classification

INGENIERÍAS Y TECNOLOGÍAS

dc.title

Sensor location for enhancing fault diagnosis

dc.type

info:eu-repo/semantics/article

dc.type

info:ar-repo/semantics/artículo

dc.type

info:eu-repo/semantics/publishedVersion

dc.date.updated

2017-10-09T15:33:52Z

dc.journal.volume

55

dc.journal.number

32

dc.journal.pagination

8830-8836

dc.journal.pais

Estados Unidos

dc.journal.ciudad

Washington D. C.

dc.description.fil

Fil: Rodriguez Aguilar, Leandro Pedro Faustino. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina

dc.description.fil

Fil: Cedeño Viteri, Marco Vinicio. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina

dc.description.fil

Fil: Sanchez, Mabel Cristina. Consejo Nacional de Investigaciones Científicas y Técnicas. Centro Científico Tecnológico Conicet - Bahía Blanca. Planta Piloto de Ingeniería Química. Universidad Nacional del Sur. Planta Piloto de Ingeniería Química; Argentina

dc.journal.title

Industrial & Engineering Chemical Research

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/doi/http://dx.doi.org/10.1021/acs.iecr.6b02288

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/url/http://pubs.acs.org/doi/abs/10.1021/acs.iecr.6b02288

Archivos asociados