Mostrar el registro sencillo del ítem

dc.contributor.author

Betancur, Stefanía

dc.contributor.author

Olmos Carreno, Carol Maritza

dc.contributor.author

Perez, Maximiliano Sebastian

dc.contributor.author

Lerner, Betiana

dc.contributor.author

Franco, Camilo A.

dc.contributor.author

Riazi, Masoud

dc.contributor.author

Gallego, Jaime

dc.contributor.author

Carrasco Marín, Francisco

dc.contributor.author

Cortés, Farid B.

dc.date.available

2022-02-08T02:41:29Z

dc.date.issued

2019-10

dc.identifier.citation

Betancur, Stefanía; Olmos Carreno, Carol Maritza; Perez, Maximiliano Sebastian; Lerner, Betiana; Franco, Camilo A.; et al.; A microfluidic study to investigate the effect of magnetic iron core-carbon shell nanoparticles on displacement mechanisms of crude oil for chemical enhanced oil recovery; Elsevier Science; Journal of Petroleum Science and Engineering; 184; 106589; 10-2019; 1-45

dc.identifier.issn

0920-4105

dc.identifier.uri

http://hdl.handle.net/11336/151524

dc.description.abstract

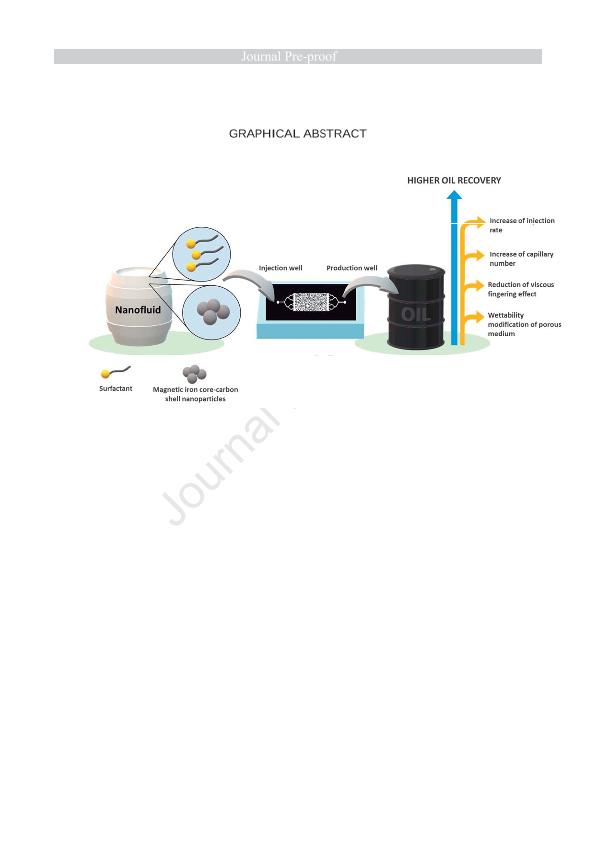

The main objective of this work is to evaluate the effect of the simultaneous use of a surfactant mixture and magnetic iron core-carbon shell nanoparticles on oil recovery via a microfluidic study based on the rock-on-a-chip technology. The surfactant solution used for all experiments was prepared based on a field formulation and consisted of a mixture of a hydrophilic and a lipophilic surfactant. Magnetic iron core-carbon shell nanoparticles with a mean particle size of 60 nm and a surface area of 123 m2 g−1 were employed. The displacement experiments consisted of waterflooding, surfactant flooding and nanoparticle-surfactant flooding and were performed using PDMS (polydimethylsiloxane)-glass microdevices type random network. The characteristics and design of the microfluidic device allowed to emulate a mixed wettability of a porous medium. Then, the oil was displaced by injecting the solution at a constant injection rate, until steady-state conditions were obtained. Furthermore, the effect of three injection rates corresponding to 0.1 ft day−1, 1 ft day−1, and 10 ft day−1 was investigated. The increase in the injection rate favored the oil recovery percentage. In addition, for all injection rates, the oil recovery decreased in the following order: nanoparticle-surfactant flooding > surfactant flooding > waterflooding. The nanoparticle-surfactant system at the injection rate of 1.9 μL min−1 presented the highest oil recovery (i.e., 84%). Likewise, nanoparticle-surfactant flooding showed a more stable displacement front and consequently, the highest capillary number among the injection fluids. Oil recovery by waterflooding was the lowest among the evaluated systems due to the viscous fingering phenomena under different injection rates. In addition, it can be observed that for all injection rates, the presence of the surfactant mixture and nanoparticles reduce the viscous fingering effect. The results can be used to visually and quantitatively analyze the role of the simultaneous use of nanoparticles with surfactants in enhanced oil recovery processes.

dc.format

application/pdf

dc.language.iso

eng

dc.publisher

Elsevier Science

dc.rights

info:eu-repo/semantics/openAccess

dc.rights.uri

https://creativecommons.org/licenses/by-nc-sa/2.5/ar/

dc.subject

MICROFLUIDIC

dc.subject

ENHANCED OIL RECOVERY

dc.subject

NANOPARTICLES

dc.subject

SURFACTANT

dc.subject.classification

Otras Nanotecnología

dc.subject.classification

Nanotecnología

dc.subject.classification

INGENIERÍAS Y TECNOLOGÍAS

dc.title

A microfluidic study to investigate the effect of magnetic iron core-carbon shell nanoparticles on displacement mechanisms of crude oil for chemical enhanced oil recovery

dc.type

info:eu-repo/semantics/article

dc.type

info:ar-repo/semantics/artículo

dc.type

info:eu-repo/semantics/publishedVersion

dc.date.updated

2022-01-25T15:07:30Z

dc.journal.volume

184

dc.journal.number

106589

dc.journal.pagination

1-45

dc.journal.pais

Países Bajos

dc.journal.ciudad

Amsterdam

dc.description.fil

Fil: Betancur, Stefanía. Universidad Nacional de Colombia. Sede Medellín; Colombia. Universidad de Granada; España

dc.description.fil

Fil: Olmos Carreno, Carol Maritza. Consejo Nacional de Investigaciones Científicas y Técnicas; Argentina. Universidad Nacional de Colombia. Sede Medellín; Colombia. Universidad Tecnológica Nacional. Facultad Regional Haedo; Argentina

dc.description.fil

Fil: Perez, Maximiliano Sebastian. Universidad Tecnológica Nacional. Facultad Regional Haedo; Argentina. Consejo Nacional de Investigaciones Científicas y Técnicas; Argentina. Universidad de Buenos Aires; Argentina

dc.description.fil

Fil: Lerner, Betiana. Universidad Tecnológica Nacional. Facultad Regional Haedo; Argentina. Consejo Nacional de Investigaciones Científicas y Técnicas; Argentina. Universidad de Buenos Aires; Argentina

dc.description.fil

Fil: Franco, Camilo A.. Universidad Nacional de Colombia. Sede Medellin; Colombia

dc.description.fil

Fil: Riazi, Masoud. Shiraz University; Irán

dc.description.fil

Fil: Gallego, Jaime. Universidad Nacional de Colombia. Sede Medellin; Colombia. Universidad de Antioquia; Colombia

dc.description.fil

Fil: Carrasco Marín, Francisco. Universidad de Granada; España

dc.description.fil

Fil: Cortés, Farid B.. Universidad Nacional de Colombia. Sede Medellin; Colombia

dc.journal.title

Journal of Petroleum Science and Engineering

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/doi/http://dx.doi.org/10.1016/j.petrol.2019.106589

dc.relation.alternativeid

info:eu-repo/semantics/altIdentifier/url/https://www.sciencedirect.com/science/article/abs/pii/S0920410519310101

Archivos asociados